Maximum accuracy in intersect drilling with Radar

The intersect method is a horizontal directional drilling technique that uses two drills, one at either end of the bore path. By means of the intersect method, drilling is done from two sides towards each other. One of the biggest advantages of the intersect method is that you can double the maximum achievable drill length. This is also the reason why there is more and more demand for the intersect method.

Intersect drilling with Radar

The underground infrastructure is becoming increasingly complex. As a result, the demand for longer drillings continues to grow. However, with longer bores, the annular pressure inside the borehole increases, raising the risk of blowouts and other damages. By using the intersect method, where drilling is performed from both sides toward a meeting point, the total bore length is effectively halved, keeping pressure levels safely below the danger zone.

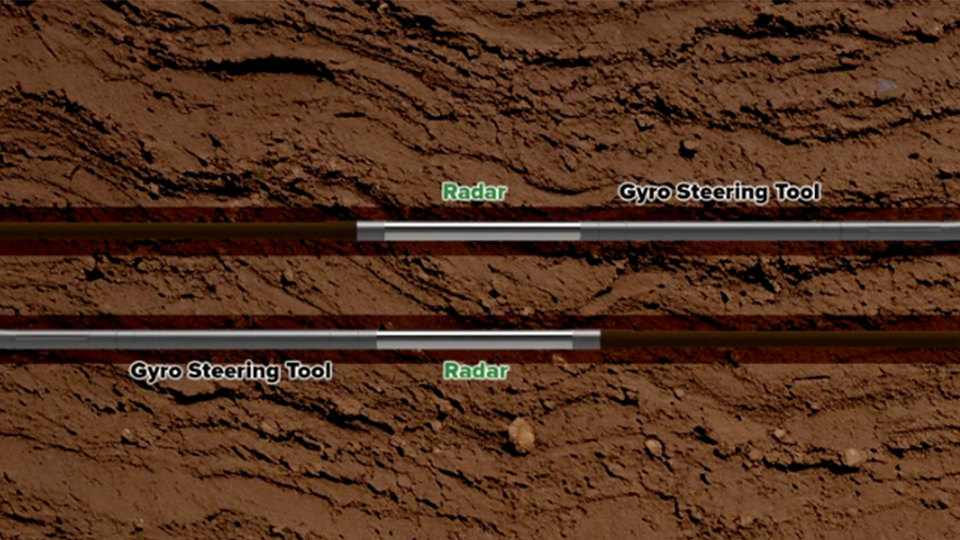

To meet the specific demands of intersect drilling, Brownline developed Radar: an integrated technology within our Drillguide steering service. Radar is used in combination with the Drillguide Gyro Steering Tool, the industry’s leading tool for real-time, highly accurate position determination during drilling. Radar makes it possible to drill from both sides with maximum precision. How does it work?

During drilling, the surveyors on both sides stay in constant communication about their progress. Because both systems are connected to the internet, they can also monitor each other’s measurements. The point and timing of the intersect are determined in consultation.

On one side, the bore is pulled back, and an attempt is made to intersect “blindly” toward the opposing borehole.

If the borehole is not found, both sides continue drilling forward until the Radar tools come within range.

As the two drill heads approach each other, the Radar modules establish communication. The relative distance between the boreholes is then automatically and accurately measured.

Thanks to these precise measurements, our surveyors can determine exactly how to drill into the opposing borehole while maintaining the minimum radius. This ensures that the boreholes connect smoothly, without abrupt bends in the drilled path (known as doglegs).

Watch the video below for a clear explanation of this process.

High precision solution

The Radar enables long-distance drilling with the highest accuracy for the entry point. In the video below, we'll explain the operation of the Radar while applying the intersect method. We have worked out another example where drills have been carried out over a length of 5 km.

Are you curious about our projects where the intersection method and our Radar have been used? Then read our case about the record-breaking drilling project in Texel.

About Brownline

Brownline is the world's leading supplier of gyro steering services for horizontal directional drilling. With groundbreaking technology and innovative tools developed by our experts, we are at the forefront of the industry. Our advanced Drillguide Gyro Steering Service provides the highest precision and reliability, making us an indispensable partner for successful drilling. We help our customers complete their drilling projects faster, more efficiently, and with unmatched accuracy.

More than 25,000 projects worldwide have been successfully completed using our solutions. Would you like to know how our steering service can take your drilling project to the next level? We would be happy to discuss the possibilities with you.

Share your drilling challenge with us

Maximize the precision of your drillings with Brownline. Our advanced Drillguide steering service ensures effortless and accurate bore paths, no matter the challenge. Get in touch with us today and discover how we can take your project to the next level!