Horizontal directional drilling

Horizontal directional drilling is a trenchless technique used for the construction of underground infrastructure. At Brownline, we use our self-engineered Drillguide Gyro Steering Tool for horizontal directional drilling. Discover the many benefits of this tool!

What is horizontal directional drilling?

Horizontal directional drilling, also called HDD, is a method that is used for trenchless drilling. Horizontal drilling is used for the placement of underground infrastructure. Such as:

water pipelines

telecommunication cables

electrical cables

gas pipelines

oil pipelines

How does horizontal directional drilling work?

Horizontal directional drilling takes place in three stages:

Pilot drilling: During the first phase, a drilling head that is hollow inside is pushed through the ground via a rig. Bentonite is poured into the hole from the surface. This is done to keep the borehole open. In addition, it immediately becomes possible to remove excess soil.

Expanding the drilling hole: After the pilot drilling, the drill gets removed and replaced with a reamer. This reamer gets pulled back to widen the drilling hole. During this process, the reamer pulls a pipeline behind it that is provided with drilling fluid to prevent it from collapsing.

Pulling the production pipe: In the final phase, the production pipe gets pulled. When the reamer has done its job, it then gets connected and replaced by the production pipe and a final reamer. Sometimes the pipeline is provided with a ballast pipe to absorb high pressure.

Brownline's Drillguide Gyro Steering Tool for HDD

A simple principle is used to control our directional drill process. An asymmetrical drill head is used in this process. This ensures that when the pipe rotates, the bore goes in a straight line. If the drill needs to change direction, we use our self-developed steering tool.

This innovative system is based on Gyro technology. Our Drillguide Gyro Steering Tool makes it possible to determine the exact position of the drill. Furthermore, our system has more advantages to make horizontal directional drilling as efficient as possible:

1. Simple setup and steering

Within an hour of arrival at the drilling rig, we are ready to start the directional drilling process. Our system has been developed in such a way that there is no need for magnetic fields or beacons to determine the position. This saves preparation time.

2. Highly accurate

As we just indicated, our tool is very accurate. The accuracy of the tool is 0.01° in pitch and 0.04° in azimuth. At the same time, the tool is not affected by magnetic fields from for example railways and cables.

3. Modular

Because of our modular and state-of-the art design, it is possible to add specific add-ons to the drill, like GPS track and Radar Intersect. The modules offer a solution for every situation, that make drilling projects possible that were previously unthinkable.

See the video below for an example of a drilling project with our Drillguide Gyro Steering Tool.

About Brownline

Brownline is the world's leading supplier of gyro steering services for horizontal directional drilling. With groundbreaking technology and innovative tools developed by our experts, we are at the forefront of the industry. Our advanced Drillguide Gyro Steering Service provides the highest precision and reliability, making us an indispensable partner for successful drilling. We help our customers complete their drilling projects faster, more efficiently, and with unmatched accuracy.

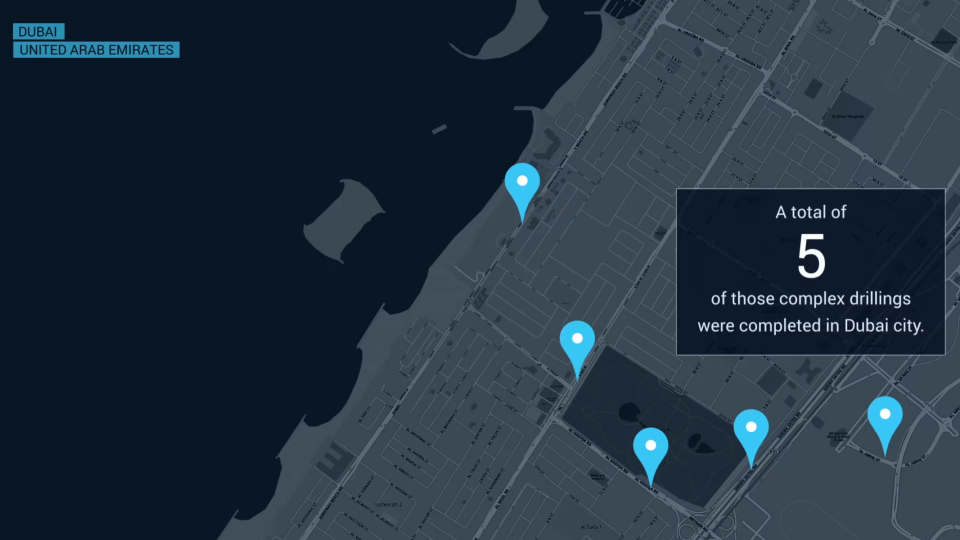

More than 25,000 projects worldwide have been successfully completed using our solutions. Would you like to know how our steering service can take your drilling project to the next level? We would be happy to discuss the possibilities with you.

Share your drilling challenge with us

Maximize the precision of your drillings with Brownline. Our advanced Drillguide Gyro Steering Tool ensures effortless and accurate bore paths, no matter the challenge. Get in touch with us today and discover how we can take your project to the next level!