Directional boring

Sewer pipes, piles and cables: these are some examples of obstacles we encounter when drilling underground. In the increasingly complex underground infrastructure, it is important to drill safely and accurately. Directional boring makes this possible! At Brownline, we use our Drillguide Gyro Steering Tool to successfully execute diverse drilling projects worldwide.

What is directional boring?

Directional boring, also known as horizontal directional drilling, involves drilling underground using a trenchless drilling technique. This method enables safe and accurate drilling without disturbing the ground level. It is often used in drilling for the installation of underground infrastructure, such as water pipelines, telecommunication cables, electricity cables, oil pipelines and gas pipelines.

The major advantage of directional boring is that most of the drilling takes place underground. Digging trenches is no longer necessary with this method. As a result, the landscape is preserved, traffic does not get hindered and there is less contaminated excavated soil. By using directional boring, projects are often completed with more time savings and lower costs compared to digging trenches.

Brownline's Drillguide Gyro Steering Tool for directional boring

In directional boring, it is essential to be able to adjust the drill head to change direction. We do this with our in-house developed Drillguide Gyro Steering Tool. Based on gyro technology, our tool measures the position of the drill head very accurate and in real-time. Our software translates the complex data from the Drillguide Gyro Steering Tool into practical information for the surveyor. The video below shows an example of a drilling project with our Drillguide Gyro Steering Tool.

Our steering service has several advantages to make directional boring as efficient as possible:

Fast setup: Thanks to the Drillguide Gyro Steering Tool, long preparation time is saved. With our system, there is no need to place magnetic fields or beacons for position determination. As a result, we are ready to start the directional boring within one hour of arriving at the construction site.

Highly accurate: The accuracy of the tool is 0.01° in pitch and 0.04° in azimuth. In addition, the tool is not disturbed by magnetic fields from railroads or cables.

Modular: The Drillguide Gyro Steering Tool is modular. We can make add-ons to the drill that enable directional boring in various situations. For example, drilling in high-risk areas with unexploded bombs with our UXOscope.

About Brownline

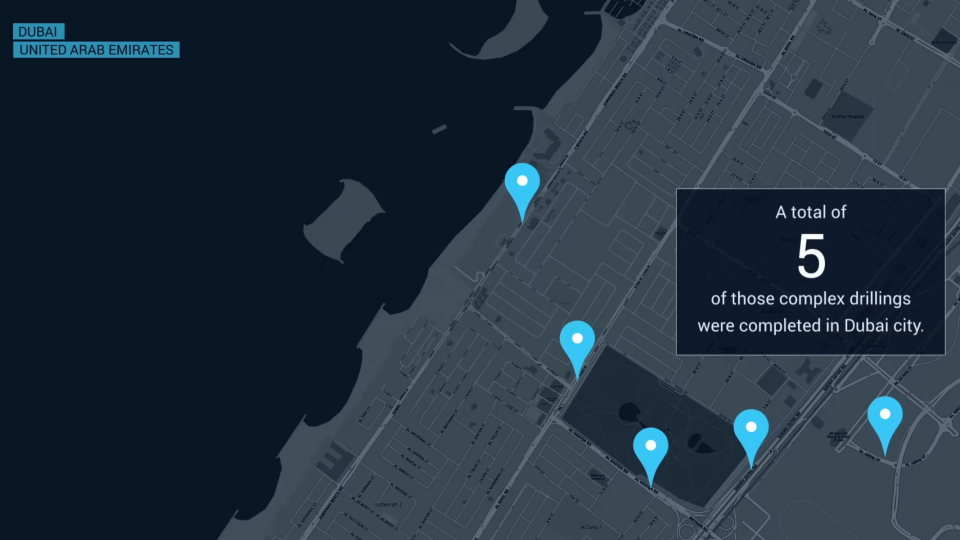

Brownline is the world's leading supplier of gyro steering services for horizontal directional drilling. With groundbreaking technology and innovative tools developed by our experts, we are at the forefront of the industry. Our advanced Drillguide Gyro Steering Service provides the highest precision and reliability, making us an indispensable partner for successful drilling. We help our customers complete their drilling projects faster, more efficiently, and with unmatched accuracy.

More than 25,000 projects worldwide have been successfully completed using our solutions. Would you like to know how our steering service can take your drilling project to the next level? We would be happy to discuss the possibilities with you.

Share your drilling challenge with us

Maximize the precision of your drillings with Brownline. Our advanced Drillguide Gyro Steering Tool ensures effortless and accurate bore paths, no matter the challenge. Get in touch with us today and discover how we can take your project to the next level!